An exceptional production site at the crossroads of Europe

The boilermarker Labbe Process Equipment has a new industrial workshop of 15 000 m² in France to manufacture high quality process equipement such as heat exchanger, pressure vessel, reactor, storage vessel and distillation column. The manufacturing of your process equipment is done without subcontracting.

Labbe Process Equipment designs and manufactures process equipments using highly developped engineering techniques, the latest calculation software and a modern workshop of 15 000 m². This development policy has been the basis of its success since its foundation, in 1948.

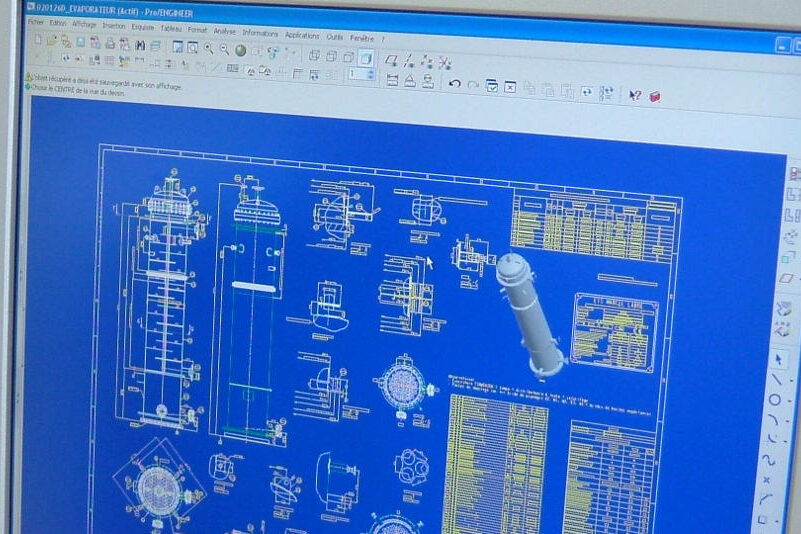

Design office

Labbe Process Equipment has its own integrated design office, thus carrying out sizing, calculation notes, construction plans as well as manufacturers’ files.

No subcontract

Labbe is fully autonomous in all the manufacturing and design phases of your boilermaking equipment thanks to significant technical resources.

Expert in welding

Labbe also offers you its welding expertise thanks to an IWE certified welding engineer

Labbe Process Equipment meets the highest demands at its production plant

Labbe manufactures process equipments made in :

Stainless Steel 304L, 316L, 316Ti, 321, 310S,

Duplex U45N, U35N,

Uranus B6,

Nickel Alloy C22, C276, C2000

The vessels can measure up to 7 meters diameter, 50 meters long and 200 Tons weight.

• 15 000 m2 factory floor and 11m height

• 4 halls 108 m long x 20 m wide x 15 m tall each

• 1 pit of 6 m diameter x 4,5m deep

• 4 factory doors 7 m wide and 7.5 m tall each

• 12 rolling cranes able to lift 10, 20, 32 and 50 tons each

The production site at Tournan en Brie has been chosen for its strategic location next to Marne la Vallée and its close links to the transport network.