Distillation column

Distillation column, absorption and stripping columns are the most widely used separation technologies in chemical industry.

Their principle is based on different components activities (boiling points or affinities). Rigorous sizing, rating and construction are required to obtain optimum column performance.

With more than half a century of experience, Labbe Process Equipment masters all steps in manufacturing distillation and adsorption towers.

This, from sizing to the construction, without subcontracting, for all types of columns:

Distillation column : vaccum, continuous, fractional distillation column, batch, reactive and complex distillation (azeotropic, pressure swing and extractive distillation)

Stripping column

Adsorption column

Rectification column

Distillation column design

As a real technical partner, Labbe advises and works with its customers. This, from the first stage of a industrial project up to the supervision on site.

Experts of Labbe use the latest calculation software to design and to manufacture our distillation tower according to all international standards.

Labbe process equipment offers you full installation of distillation process with boilers, reboiler, distillation column, condenser and vessel.

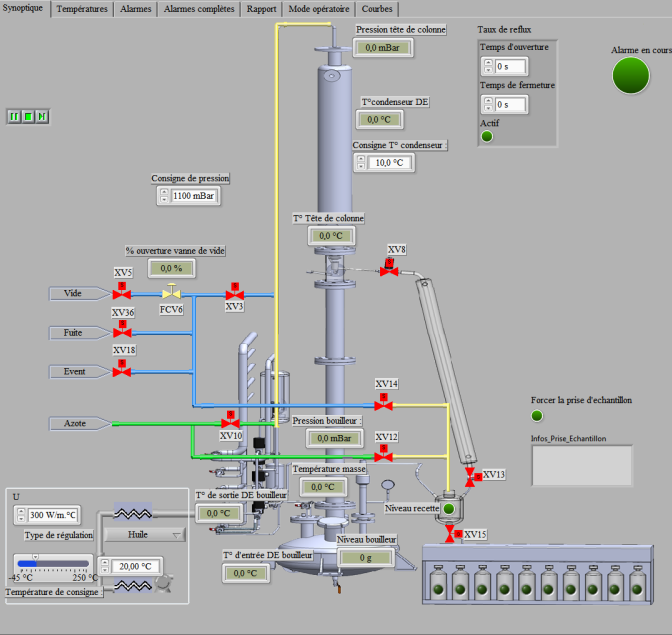

Furthermore, Labbe proposes you the automation of the distillation equipment.

Distillation column manufacturer

Thanks to our unique production methods and facilities, Labbe meets competing demands at its production plant in France.

Labbe Process Equipment manufactures distillation columns made of stainless steel, duplex, incoloy and hastelloy.

Columns can measure up to 7 meters diameter, 50 meters long and 200 Tons weight.

In its industrial workshop of 15.000 m², Labbe controls every step of the distillation apparatus production process :

cutting, dished heads forming, rolling, machining, welding, mounting of internals, polishing, testing, pickling and passivation.

Labbe process equipment supplies columns and internals with short delivery times.